- Symbol: W

- Category: Transition Metal, Group VI

- Atomic Number: 74

- Density: 19.25 g / cm3

- Melting Point: 3420 °C, highest metal, 2nd highest of elements

- Discovered: 1781

- Low vapor pressure

- High electrical resistance

- Low coefficient of thermal expansion (CTE)

- High density

- Strong corrosion resistance

- High elastic modulus

- ≥ 99.95% W, guaranteed

- 99.997% W, typically analyzed

- ≥ 99.9995% W, available

Alloys

- Lanthanated 1.0% & 1.5% La2O3

- Tungsten Heavy Alloys (W-Ni-Fe-Co)

- Potassium doped tungsten (WK)

UB Grade: 3.2-4.2 Micron Average Particle Size (Fisher), -150 Mesh (Tyler)

UX Grade: 1.5-5.0 Micron Average Particle Size (Fisher), -150 Mesh (Tyler)

- 1.5 µm UX

- 3.0 µm UX

- 3.6 µm UX

- 5.0 µm UX

Standard Purity, 99.95% W

High Purity, 99.9995% W

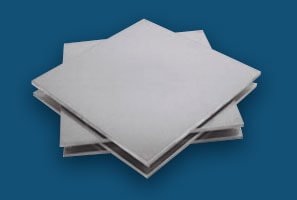

The tungsten sheet surface can be supplied in a shiny, matte, satin, or as-rolled condition; dependent upon thickness and width parameters.

Elmet produces Tungsten flat products in thicknesses from .025 to over 1 inch. Tungsten flat material from .025″ to .09″ inches in thickness is classified as sheet. Tungsten flat material from .1 and larger is classified as plate.

- All Rod Products are made from 99.95% pure tungsten pressed, sintered and swaged material

- Made in the USA and the only fully integrated US manufacturer of pure tungsten and molybdenum rod

- Designed to exceed ASTM F288 specifications

- ISO 9001 and AS9100C certified manufacturing process

Tungsten (Wolfram) and Advanced Alloys – High-Performance Materials for Extreme Conditions

Tungsten (W) is one of the most remarkable and robust metals used in modern industry. With the highest melting point of all metals – 3420°C, an exceptionally high density of 19.25 g/cm³, outstanding corrosion resistance, low thermal expansion and a very high elastic modulus, tungsten is the preferred choice for components operating under extreme thermal, mechanical and energetic stress.

Tungsten is widely utilized across advanced industrial systems, semiconductor manufacturing, medical and X-ray technologies, high-energy equipment, and selected defense applications where extreme density, thermal stability and structural reliability are essential.

Key Material Characteristics

-

Melting point: 3420°C – the highest of all metals

-

Very high density: 19.25 g/cm³

-

Extremely low vapor pressure

-

Low coefficient of thermal expansion (CTE)

-

Strong corrosion resistance

-

Very high elastic modulus / mechanical stiffness

-

High electrical resistivity

Purity Grades

Available in multiple purity levels:

-

≥ 99.95% W – guaranteed

-

99.997% W – typical chemical analysis

-

≥ 99.9995% W – Ultra High Purity

Advanced Tungsten Alloys

Lanthanated Tungsten – 1.0% / 1.5% La₂O₃

Improved high-temperature performance, enhanced grain stability and extended service life.

Tungsten Heavy Alloys (W-Ni-Fe-Co)

High-density alloys designed for:

• High-energy radiation shielding

• Counterweights and balancing components

• Defense structures

• Critical load-bearing elements

Potassium-Doped Tungsten (WK)

Optimized for heating, vacuum and high-temperature applications with superior creep resistance.

Products and Manufacturing Capabilities

Tungsten Powders

Available particle sizes and grades:

-

UB Grade: 3.2–4.2 µm, −150 Mesh

-

UX Grade: 1.5–5.0 µm, −150 Mesh

-

1.5 / 3.0 / 3.6 / 5.0 µm variants

-

Standard Purity: 99.95% W

-

Ultra-High Purity: 99.9995% W

Suitable for powder metallurgy, sintering, sputtering and high-precision manufacturing.

Tungsten Sheet

Surface finishes: shiny, matte, satin, or as-rolled.

Applications include:

-

Vacuum coating equipment

-

High-temperature components

-

X-ray & high-energy shielding

-

Industrial tooling

-

Structural parts for scientific and defense systems

Tungsten Plate

Thickness range: 0.025″ to over 1″

Classification:

-

0.025″–0.09″: sheet

-

0.1″ and above: plate

Applications:

• Sputtering targets

• Vacuum furnace components

• Radiation shielding plates

• Machining blanks

Tungsten Rod

Manufactured from 99.95% pure pressed–sintered–swaged tungsten.

Features:

-

Fully U.S.-made production

-

Exceeds ASTM F288 requirements

-

Produced under ISO 9001 and AS9100C certification

Used for structural parts, high-temperature elements, energy systems and precision assemblies.

Pure Tungsten Wire

Available in extremely fine diameters.

Applications include:

-

Lighting

-

Heating elements

-

Electronics

-

Miniature components

-

Vacuum furnace frames

Tungsten Machining & Fabrication

-

CNC machining (turning, milling, shaping)

-

EDM cutting

-

Grinding & polishing

-

Forming, deep drawing and shaping

-

Precision parts for vacuum, high-heat and high-energy systems

Applications in Industry and Defense

Advanced Industrial Systems

✔ High-temperature & vacuum furnaces

✔ Semiconductor manufacturing

✔ Laser and precision thermal systems

✔ Heavy shielding and thermal protection

✔ Sputtering targets and coating systems

Medical, Research & X-Ray

✔ High-energy particle shielding

✔ Collimators

✔ Thermal & emission components

Defense Applications (discreet and non-sensitive)

✔ Heavy shielding plates

✔ Counterweights for defense systems

✔ High-energy impact and radiation shielding

✔ Structural parts for high-temperature and laser-based platforms

Summary

Tungsten is one of the densest, strongest and most thermally stable materials available. Combined with advanced alloys such as Lanthanated Tungsten, WK, and Tungsten Heavy Alloys, it enables the production of highly reliable components for industrial, scientific and defense environments requiring maximum performance under extreme conditions.

We supply raw materials, semi-finished products and full machining capabilities — all produced to high standards with consistent, long-term quality.