What are Frameless Direct Drive Torque Motors?

Frameless direct drive torque motors are high-performance brushless motors designed as separate rotor and stator components. Unlike traditional housed motors, they are integrated directly into the host machine’s mechanical structure. This frameless design eliminates couplings, gears, and belts, reducing backlash and torsional resonances while maximizing stiffness and dynamic response.

The large through-bore available in most models provides additional design flexibility, enabling routing of cables, optics, air, or fluid systems directly through the motor center. These characteristics make frameless torque motors ideal for precision applications requiring smooth motion, high torque density, and reliability.

The Megaflux™ Motor Family

Allied Motion’s Megaflux™ frameless direct drive torque motors cover a broad performance spectrum. With 12 standard frame diameters from 60 mm to 330 mm (2.4 to 13 in.) and multiple stack lengths, the Megaflux family ensures that an optimized motor can be matched to almost any application.

-

Continuous stall torque: from 0.3 Nm up to 181 Nm

-

Through-bore aperture: up to 582 mm (22.9 in.)

-

Voltages: standard windings available in 48, 150, and 300 VDC

-

Performance focus: high torque at low speeds, zero backlash, smooth motion

Custom modifications, unique winding designs, and fully tailored solutions are also available to meet demanding application requirements.

Series Overview

The table below summarizes the key specifications of the Megaflux™ frameless direct drive torque motor series:

| Series | OD (mm) | Max. ID (mm) | Stack Length (mm) | Voltage (VDC) | Cont. Stall Torque (Nm) | No-load Speed (RPM) |

|---|---|---|---|---|---|---|

| MF0060 | 60 | 36 | 8–55 | 48 / 150 / 300 | 0.3 – 1.0 | 2076 – 7098 |

| MF0076 | 76 | 47 | 8–55 | 48 / 150 / 300 | 0.5 – 2.2 | 1640 – 6447 |

| MF0095 | 95 | 58 | 8–55 | 48 / 150 / 300 | 0.9 – 4.4 | 1300 – 5436 |

| MF0127 | 127 | 84 | 8–55 | 48 / 150 / 300 | 1.6 – 8.4 | 939 – 5097 |

| MF0150 | 170 | 74 | 10–101 | 48 / 150 / 300 | 3.1 – 25 | 416 – 2500 |

| MF0210 | 230 | 130 | 10–101 | 48 / 150 / 300 | 8 – 75 | 338 – 1894 |

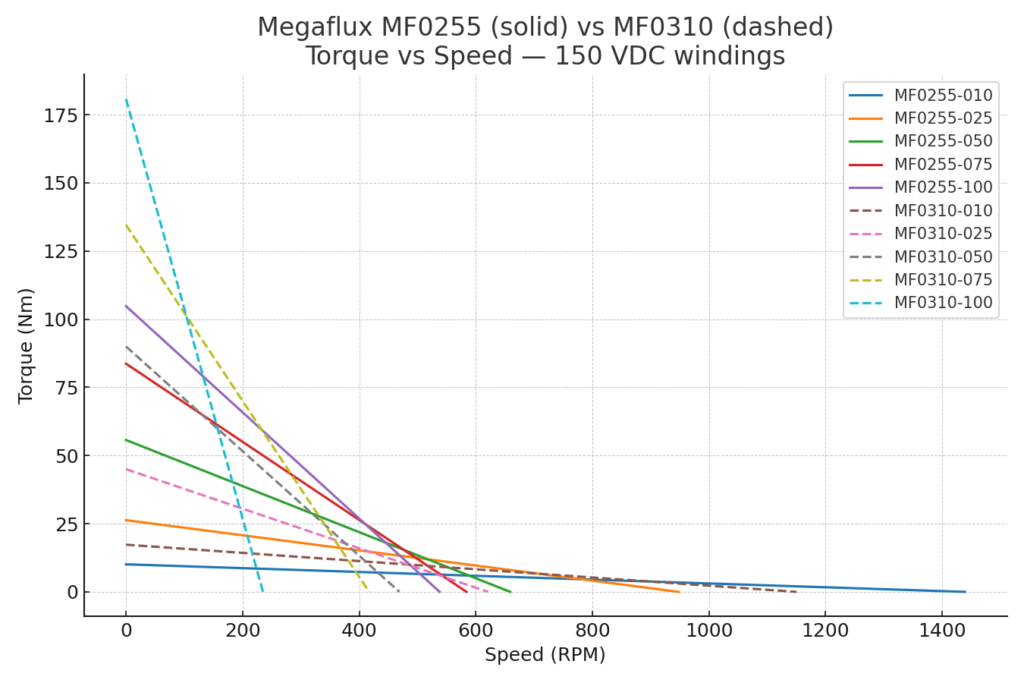

| MF0255 | 275 | 172 | 10–101 | 48 / 150 / 300 | 10 – 103 | 280 – 1591 |

| MF0310 | 330 | 210 | 10–101 | 48 / 150 / 300 | 17 – 181 | 100 – 1260 |

Typical Applications

Frameless direct drive torque motors are widely adopted in:

-

Robotics and automation – for high-precision joints, collaborative robots, and pick-and-place machines.

-

Aerospace and defense systems – gimbals, turrets, and stabilization platforms where reliability and accuracy are critical.

-

Medical imaging and diagnostics – CT scanners, MRI tables, and robotic surgical systems requiring smooth motion with zero backlash.

-

Semiconductor and electronics manufacturing – wafer handling, inspection stages, and alignment systems.

-

Industrial machinery – rotary tables, indexing systems, and packaging lines needing high torque at low speed.

-

Optics and photonics – telescope mounts, optical alignment stages, and laser systems.