In modern electrical and control systems, every action — even the smallest one — must be monitored, recorded, and controlled.

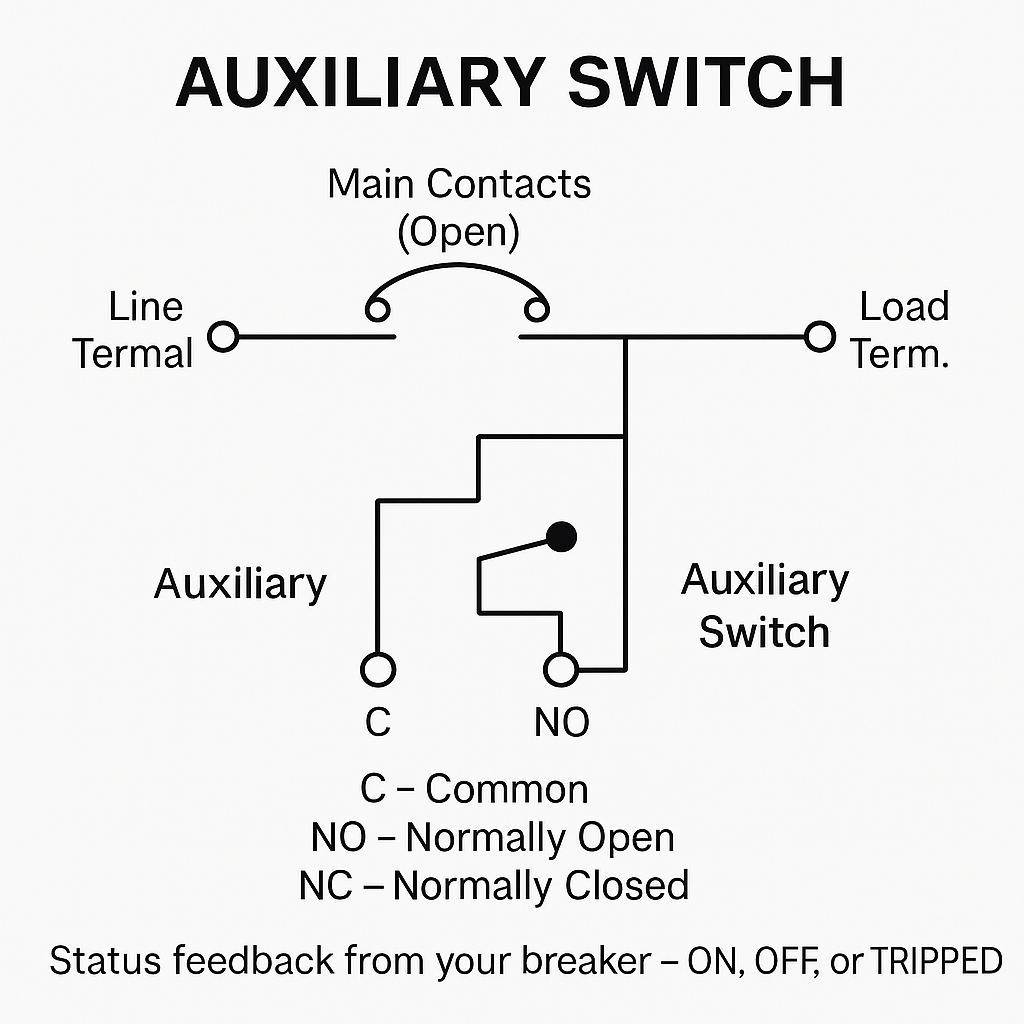

The Auxiliary Switch is a smart yet simple component designed to tell the system what’s really happening inside the breaker:

whether it is ON, OFF, or has tripped due to a fault.

🔹 What Is an Auxiliary Switch?

An auxiliary switch is an additional electrical contact unit that is electrically isolated from the main power circuit, yet mechanically synchronized with the main contacts of the breaker or magnetic protector.

In simple terms — when the main breaker opens or closes, the auxiliary switch changes its state simultaneously, sending a signal to the control system.

The contacts may be:

-

NO (Normally Open) – closed when the breaker is ON.

-

NC (Normally Closed) – opened when the breaker is ON.

-

Or a combination of both in a single SPDT (changeover) structure.

🔹 Why It Matters

In critical environments — defense, industrial, or medical — there’s no room for guesswork.

A control system or load-management computer must know, in real time, whether a breaker has been activated, tripped, or manually switched off.

The auxiliary switch provides this information reliably, precisely, and instantly.

Key advantages:

-

Remote monitoring and control – allows PLC or SCADA systems to track breaker status in real time.

-

Smart maintenance and alerts – forms the basis for alarms and automated fault diagnostics.

-

Safety integration – enables timed disconnection or prevents unintended restart after a trip.

-

Isolation between power and control circuits – keeps low-voltage control (e.g., 24 VDC) separate from high-voltage power (e.g., 230 VAC).