A Critical Design Consideration in Industrial, Medical, and Defense Systems

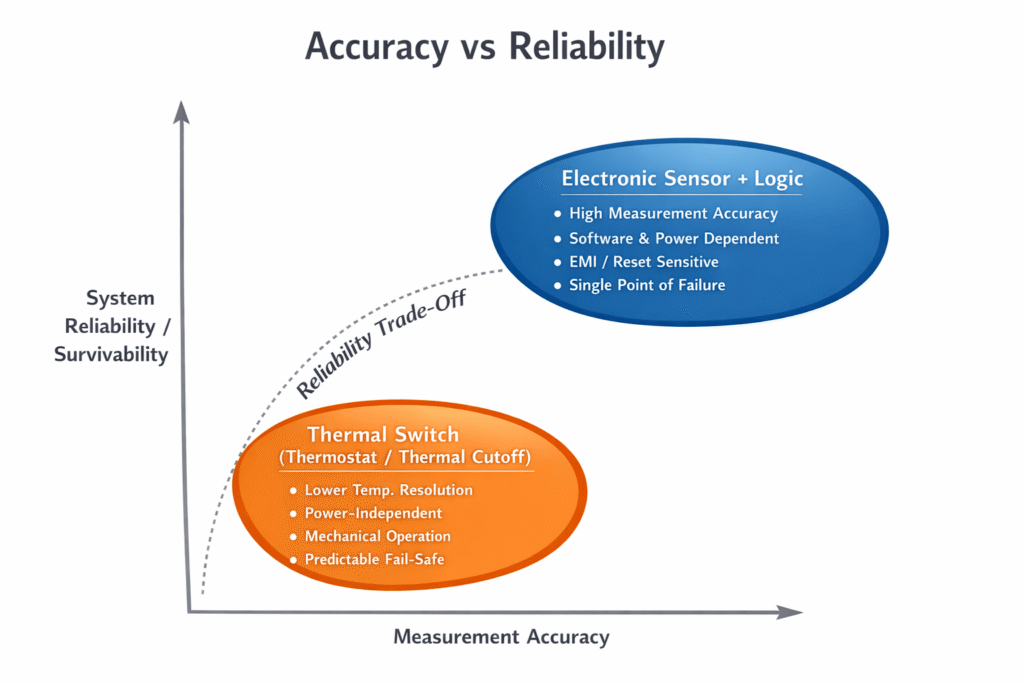

In many systems, the choice between a simple thermal switch and a temperature sensor combined with electronic logic is often perceived as a question of accuracy.

In practice, this decision is far deeper – involving reliability, safety, failure modes, and the system’s ability to survive edge-case scenarios.

In this article, we examine when the simpler solution – a thermal switch – is actually the correct engineering choice.

Two Approaches to the Same Problem

How Do We Protect a System Against Overheating?

At the architectural level, two common approaches are used for thermal protection:

Approach A – Temperature Sensor + Logic

The system includes:

-

A temperature sensor (NTC / PTC / PT100 / IC)

-

Measurement via MCU or PLC

-

Software-based decision making

-

Relay activation or load disconnection

Advantages:

-

High measurement accuracy

-

Operational flexibility

-

Continuous monitoring, logging, and diagnostics

Disadvantages:

-

Full dependency on software

-

Dependency on power availability

-

Sensitivity to EMI, resets, and watchdog behavior

-

Multiple potential failure points

Approach B – Thermal Switch (Thermostat / Thermal Cutoff)

The system includes:

-

A mechanical, bimetallic, or wax-based device

-

Physical disconnection at a predefined temperature

-

Autonomous operation, without code or logic

Advantages:

-

True fail-safe behavior

-

Operates even without power

-

Predictable and deterministic response

-

Independent of software

Disadvantages:

-

Lower temperature resolution

-

Fixed or limited adjustable setpoint

-

No continuous temperature information

The Real Question: Accuracy – or Survivability?

During the design phase, many engineers naturally gravitate toward the more accurate solution.

However, in safety-critical systems, the more important question is:

What happens when the system does not behave as expected?

-

What happens during an unexpected reset?

-

What happens under electromagnetic interference?

-

What happens during a power loss?

-

What happens when the software becomes unresponsive?

At this point, accuracy is no longer the primary parameter.

When a Thermal Switch Is Clearly the Better Choice

Scenarios Where Simplicity Wins

Fail-Safe Is a Fundamental Requirement

In medical equipment, safety systems, and unmanned platforms,

a device is required that can disconnect the system even when everything else has failed.

A thermal switch provides a protection layer that does not depend on any external condition.

Power Loss Is a Realistic Scenario

In battery-powered systems, automotive, rail, or field equipment,

thermal protection that does not require power is a critical advantage.

A “Noisy” Environment

EMI, transients, current surges, and voltage spikes can cause:

-

Incorrect sensor readings

-

MCU resets

-

Unpredictable logic behavior

The mechanical device continues to operate normally.

Regulatory Requirements

In many standards, the following is required:

-

An independent physical disconnect device

-

Not dependent on software

-

Not bypassable by firmware

In these cases, a sensor and logic alone are not sufficient.

Not Either-Or, but Both

In well-designed systems, the correct architecture is a combination:

| Layer | Function |

|---|---|

| Sensor + Logic | Control, monitoring, prediction |

| Thermal Switch | Emergency shutdown – last line of defense |

As a result:

-

Software controls

-

Hardware protects

How to Select the Right Thermal Switch

Without diving into catalogs, key considerations include:

-

Trip temperature relative to ambient conditions

-

Hysteresis

-

Contact type (NO / NC)

-

Rated current and voltage

-

Installation method – true thermal coupling

-

Long-term reliability (number of cycles)

Summary

The choice between a temperature sensor and a thermal switch is not merely a technological decision –

it reflects the system’s risk philosophy.

In critical systems:

Simplicity = Survivability